How to choose a fiber optic fusion splicer (welding machine, or splicing machine)

Background

Since optical fiber start for business application in mid 1980s, its about 30 years now. people right now adequate to the benefits of it. and it is widely used worldwide, no matter in developed country or developing country, however, it is a challenge for the engineer to find a cost effective fusion splicer. Even through, most people in the fiber optic industry many years and know what fusion splicer is and its applications. Nowadays, there are so many optic fusion splicer manufacturer and OEM service in the market,

and this still make us confuse to choose the best fusion splicer provider. Here we will discuss about how to find the best fusion splicer for your application in the following aspects:

1. Core Alignment Fusion Splicer Introduction

2. Cladding Alignment Fusion Splicer Introduction

3. FAQ for choose fusion splicer

4. Tips for get better fusion splicing result

What is Fusion Splicer?

The fusion splicer is used for splicing two optical fibers end-to-end by fusion (sometimes we say, welding or heating). The goal is to fuse the two fibers together in such a way that light passing through the fibers is not scattered or reflected back by the splice, and so that the splice and the region surrounding it are almost as strong as the virgin fiber itself. The source of heat is usually an electric arc, but can also be a laser, or a gas flame, or a tungsten filament through which current is passed. A good automatic fusion splicing machine (welding machine), which can work automatically and with more permanent connection compared with mechanical splice, with low-loss, high-strength joint. It is a indispensable tools for fiber OSP and indoor cable network installation.

Currently, There are two aligning system used for fusion splicer which is Core alignment system and cladding alignment system.

1. Core alignment Fusion Splicer

Some Fusion Splicer supplier, no matter from Japan, Korea or China, also mention there fusion with PAS (Profile Alignment System) for excellent fusoin splicing performance. Acually it is Core Alignment system. Active alignment of the cores, or core alignment fusion

splicing, is currently the most commonly used fusion splicing technology. It is more expensive for its complex technology, more powerful and flexible, and less sensitive to variations in the cable and environment. Core alignment splicers use a combination of image and light detection systems that ‘view’ the fibre cores to measure and monitor core position during the alignment process, we will explain more in the following paragraph. Fibre cores are placed in V-grooves and are adjusted horizontally (X-axis), vertically (Y-axis) and in/out (Z-axis) to allow core-to-core alignment. The ability to control core location on fibre results in improved splice performance, as the splicer can compensate against influences such as fibre offset due to contamination or core-cladding concentricity mismatches.

The splicer uses various methods to see the fibres. It uses that input to have precisely controlled motors (some with 4 motors, some splicer with 6 motors for more accurate adjustment) move the fibres along their X-axis (horizontal), Y-axis (vertical) and Z-axis (in and out) axes until they are aligned The PAS System “sees” the core by detecting the refraction of light caused at the core-cladding interface. Images are taken in two orthogonal planes so that the core can be located precisely The splicer uses a V-groove to hold the fibres in place and moves the V-groove along the X, Y, Axis until the cores are aligned in both views

2. Cladding alignment

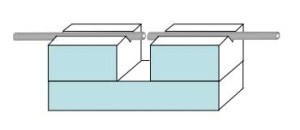

Clading alignment also named as Passive Alignment or Fixed V-groove type. It is a passive alignment that relies on the accurate pre-alignment of fibre V-grooves that grip the outer surface or cladding of the fibre. Fiber cores are adjusted inwards and outwards. The advantage of this method is that the technology required is low cost and fast alignment and splicing, so it is still utilised on low-cost field fusion splicers and ribbon splicers. Fibre position, core-cladding eccentricity and mode field diameter (MFD) influence the effectiveness of cladding alignment and subsequent splice performance. Fibre position is influenced by contamination on the fibre or V-grooves. While the

operator controls this parameter, core-cladding eccentricity and MFD are fibre manufacture parameters, and typically come into consideration when splicing new to old fibres and also dissimilar fibres such as single mode G652.D to G657.A.

The fibres placed in a fixed V-groove that relies on the concentricity of the outside of the glass to align them in along the X and Y axises. Z alignment is done by the splicer or the user (in manual machines). Typically, this is referred to as a fixed V-groove.

The only movement of the fibers is along the Z axis as the splicer brings the fibres together. This process relies heavily on precisely-shaped V-grooves and very clean fiber. Chipped V-grooves or dirty fibres can affect the X or Y alignment to the point that the splicer cannot perform a good splice on them. Passive alignment relies on the core being central within the fibre. If the core is offset then losses will be higher – this is particularly true with singlemode where the cores are very small and a very small offset can lead to high losses

3. FAQ for choose fusion splicer

Q: List of Fiber optic fusion splicer brand in the market ?

A: Japan: AFL/FUJIKURA, SUMITOMO, FITEL (FURUKAWA), Korea: INNO, Ilsintech, China: CETC 41, JILONG, DVP, etc

Q: Which brand enjoy world reputation?

A: FUJIKURA is the best over the world with high price.

Q: Price Level For Fusion Splicer?

A: Japan Fusion Splicer: Over USD7000

Korean Fusion Splicer: Over USD5000

China Fusion Splicer: Over USD3000

Q:Optical Fiber fusion splicer Type:

A: single core Fiber fusion splicer,Ribbon fiber Fusion splicer, special fiber fusion splicer

Q: Different type of Fusion splicer:

A: The principle of fusion splicer is same, Single core optical fiber welding machine can fuse a single core each time; Ribbon fiber Fusion splicer used for weld ribbon fiber, able to splice 2/4/6/8/12 cores onece.

Q: Which type Fiber Fusion Splicer welding speed is most fast.

A: New Sumitomo TYPE-81C welding speed is most fast.

4. Tips for get better fusion splicing result

4.1. When working with fiber, keep in mind that particles not visible to the naked eye could cause tremendous problems when working with fiber optics. Thoroughly and frequently clean your splicing tools. “Excessive” cleaning of your fiber and tools will save you time and money down the road.

4.2. Properly maintain and operate your fiber cleaver. The fiber cleaver is your most valuable tool in fiber splicing. a good fiber cleaver could perform a good cleave to the fiber core, which will increase the alignment speed for the fusion splicer and have a good fusion quality, which is low loss for the fiber

4.3. Fusion parameters must be adjusted minimally and methodically (fusion splicing only). If you start changing the fusion parameters on the splicer as soon as there is a hint of a problem you might lose your desired setting. Dirty equipment should be your first check and them continue with the parameters. Fusion time and fusion current are the two key factors for splicing. Different variables of these two factors can produce the same splice results. High time and low current result in the same outcome as high current and low time. Make sure to change one variable at a time and keep checking until you have found the right fusion parameters for your fiber type.

Summary

As always, best practice extends further than having the right piece of equipment. Maintain a clean and contamination-free work area by regularly cleaning stripping tools, cleaver blades and pads, V-grooves, camera lenses, mirror and splicer travel case. Observe safety precautions such as disposing of fiber cut-off in sharps containers. Regular operator maintenance of equipment is also vital – this includes arc calibration, electrode stabilisation and battery cycling, as well as monitoring cleaver performance and adjusting cleaver blade position when required. Using manufacturer’s original consumables such as electrodes and cleaver blades will enhance your equipment’s performance. Using endorsed services centres ensures access to manufacturer-trained and certified technicians, and manufacturer original parts and firmware.