Cabling is an increasingly important topic in the data center. This focus is growing with the proliferation of 10 Gb/s and 40 Gb/s cables in volume today, with 100 Gb/s cables already starting deployments, and with both intra-rack and inter-rack applications.

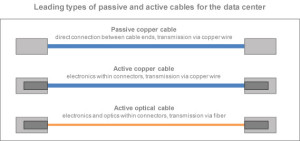

Passive cabling provides a direct electrical connection between corresponding cable ends. Active cables provide the same effect but, by embedding optics and/or electronics within the connectors, can overcome some of the limitations of passive cables. While passive cables are always copper-based, active cables can use either copper wire or fiber optics to provide the link between the cable ends.

As a data center manager or planner, why do you care about these distinctions? And what are the significant strengths and weaknesses of each?

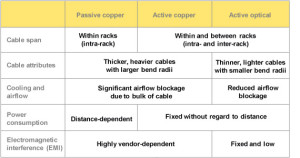

The following table highlights five key attributes and characterizes each of these cable types. After the table you’ll find more explanation of each of these attributes.

Cable span: Traditional passive copper cables are primarily deployed today to connect equipment within a single rack (intra-rack connections). Depending on the cable type and application, they are typically limited in distance to 7-10 meters. By contrast, an active cable has electronics and possibly optics embedded within the connectors on each end, allowing the cable to overcome most physical distance limitations. In the case of active copper cabling, electronics in each end of the cable can boost, equalize and otherwise treat the signals going onto the copper wire, and the electronics on the other end then restores them to original levels, allowing cable distances suitable for use within racks and between racks (inter-rack). In an active optical cable, the connectors translate electrical signals to optical ones, and vice-versa, allowing longer distances, and providing even greater data center configuration flexibility. With active optical cables, the same cable technology can serve both intra- and inter-rack applications.

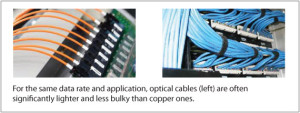

Cable attributes: For equivalent data rates, optical cable is thinner and lighter than copper wire, and it does not need to be shielded. For these reasons, an optical cable is often lighter in weight and less bulky, and has a smaller bend radius, than the equivalent copper cable, especially with longer cables. These advantages of fiber provide more data center configuration flexibility.

Cooling and airflow considerations: The physical volume of large numbers of cables can have significant effects on the cooling efficiency and lifetime of the connected equipment, as well as the cooling requirements and power consumption of racks and the entire data center facility. Thin, lightweight optical cables have a clear advantage in this regard.

Power consumption: Today, cables consume relatively little power when compared to processors and other components, or to fans and cooling. But as those systems are becoming more energy efficient, the focus on cable energy consumption is growing. As a rule, the amount of energy dissipated, and the amount of power required to transmit over a passive copper cable is directly related to its length. Active cables, both copper and optical, tend to have fixed power consumption without regard to their length. Finally, the superiority of optics for longer cable distances is well known.

Electromagnetic interference (EMI): Electromagnetic radiation from copper cables, whether passive or active, is highly dependent on the quality standards of the manufacturer, and with copper cables both the connectors and the conductors can emit EMI. The low cost of third-party passive copper cables is often attractive, but their EMI characteristics can be very unpredictable. With active optical cabling, EMI can come only from the components within the connectors on the cable ends, since the cable itself emits no electromagnetic radiation. As a general rule, these optical components are more carefully designed and shielded that their copper cable equivalents. As a result, optical cables tend to be superior from an EMI perspective.

Other issues to consider

Here are some other considerations you may want to keep in mind when making data center cable decisions:

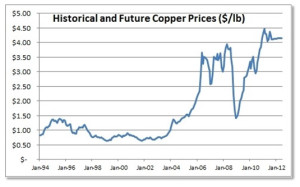

Cost: The price of copper can be volatile (see chart), but the cost of fiber cables is falling, as manufacturing volumes increase and the technology continues to improve. Some analyses show that, when lifetime costs like deployment, cooling and energy consumption are considered, fiber solutions are more cost-effective. Over the long term, copper prices, ignoring the volatility, are rising, as evidenced by the growing number of thefts of copper wire.

Source: Seeking Alpha

On-board vs. cable-based equalization: There is discussion of the merits of performing signal processing and equalization within cables, as opposed to doing it inside the ports being connected. As noted earlier, cable of different lengths may have different operating characteristics. As a result, performing these functions within the cable has the advantage of insulating the connected devices from any distance-related configuration or performance issues.

Questions to ask your data center cable supplier

Asking these questions will allow you to have a meaningful conversation with your provider about cable products and directions:

Cable types: On what basis are you recommending various cable solutions to us? What are your recommendations about choices between passive copper, active copper and active optical cabling?

Power consumption and cooling: How can we minimize the cooling obstacles caused by cabling?

Electromagnetic interference: What steps do you take to control EMI from your copper cable products?

Cable manufacturers: Can you tell us who manufactures the cables you recommend to us?