Nowadays, fiber cable are installed world wide, even through there is many protection for optical cable, however, it is still easily damaged because the hair like bare fiber is easy to break. to avoid fiber break, and ensure the fibre cable are correctly installed with good optical performance. please read the following guide lines carefully and thoroughly.

Optical fiber requires special care during installation, to ensure reliable operation. Installation guidelines regarding minimum bend radius, tensile loads, crush resistance of cable must be followed. Cable connectors should wear cap to protect from contamination and scratching at all times. Violation of any of these parameters causes increased attenuation or permanent damage to the cable. The following comments to be considered for installing optical cables.

1. DONOT exceed the Max. cable length

Check the cable specification first before installation, for the appropriate cable lengths to ensure proper operation. You may experience additional attenuation loss when using bulkhead connectors to join cables even when the total length is less than the maximum allowed. Care should be used in maintaining total attenuation budget when joining cables with bulkhead connectors.

2. DoNOT bending less than the Min. Bending radius

Short term or long term small bend radius of the cable can cause unseen damage to the fiber cables. This may result to an expensive re-installing of cables later.

3. Avoiding twist the fiber cable

Use proper pulling techniques when installing the cables. Putting twists in the cable greatly increases the chances of breaking the fibers.

Fiber Optic Cable Pulling Techniques

Installation methods for both wire cables and optical fibre cables are similar. make sure to remember the following items:

- Direct pulling the cable connector may damage it, because it is not designed for direct pulling

- Use pulling grips designed for pre-connected fiber optic cables. Grips with a fixed pull ring should use a swivel to attach the pull rope.

- Monitor the tension. Donot exceed the max. tension load.

1. On runs from 40m to 100m, use proper lubricants and make sure they are compatible with the cable jacket.

2. On runs over 100m, use proper lubricants and pull from the middle out to both ends.

3. If possible, use an automated puller with tension control or at least a breakaway-pulling eye. - Straight pulling. Use cable guides to maintain the recommended cable bending radius. Do not make the bending radius smaller than the cable bending radius. smaller bend radius harms the fiber.

- Use a swivel-pulling eye, to prevent additional twisting of the cable during installation

Routing Fibre Optic Cables

Take care to properly route cables through cabinets and right angle bends within cable tray.

- Install cables in containment without loops.Avoid placing fiber optic cables in containment and conduits with copper cables to avoid excessive loading or twisting.

- Protect cables from excessive or frequent bending.Cables do not have a flex rating. Special care must be taken to protect the cable and to avoid exceeding the bend radius of the cable.

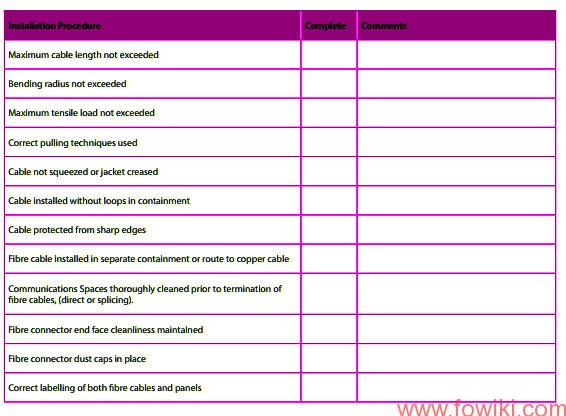

Installation Checklist

Use the following installation checklist to ensure proper handling.

Cleaning Techniques for Fibre Optic Cables

Any contamination in the fibre connection can cause failure of the component or failure of the whole system. Even dust can cause a variety of problems for optical connections. In a survey carried out by Fluke Networks they claim that 85% of the failing links can be attributed to ‘end-face contamination’.

Proper cleaning of the fibre optic cable ends and transceivers is essential to minimize system attenuation.

Dirty fibre optic connectors cross contaminate their mating transceivers. Conversely a dirty transceiver contaminates its mating fibre optic connector. There are a variety of ways to clean fibre optic components. Pre-packaged wipes, swabs and, canned air are suitable. Whatever the choice, it is important to follow the correct procedure/instructions. Failure to do so could lead to even more contamination being introduced.

The following is a flow chart outlining the suggested Excel process for cleaning fibre connectors.

Conclusion

Cleaning fibre is an essential process of any installation and there are a number of key elements to ensure success.

- Never touch the end-face of the fibre connectors – natural body oil can be a major cause of contamination

- Always keep a protective cap on unplugged fibre connectors – protection from both damage and contamination

- Do not clean bulkhead connectors without a way of inspecting them – how else will you know whether the cleaning is successful?

- Always store unused protective caps in a sealed container – they can also be a major source of contamination if not stored in a clean environment.

- Donot re-use any tissue, swab or cleaning cassette reel

- Donot touch any portion of tissue or swab where alcohol was applied – you could be introducing both dirt and body oil

- Donot use wet cleaning method without a way of dry cleaning immediately afterwards – the wet process can leave a harmful residue that is hard to remove when it dries

Make sure all the fiber connectors you intend to clean are not online. Please also sure not directly look at the connector end face, for there might be laser from the connector, and hurt you eyes.