OTDR FAQ Gathering

AFL Global OTDR FAQ

OTDR FAQ 1: When do I need to use a launch cord (cable) with my OTDR?

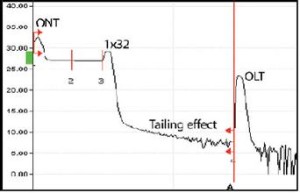

A: A launch cord ‘moves’ the effects of the OTDR’s own front panel connection away from the first connection in the link under test. This allows the OTDR to measure the loss and reflectance of first connection in the link. However, a launch cable will not eliminate the so called ‘dead zone’ after the first connection in the link.

OTDR FAQ 2: When do I need to use a tail cord (receive cable)?

A: A tail cord creates OTDR backscatter after the final connection in the fiber link under test and therefore is needed to measure the loss and reflectance of the final connection in the link

OTDR FAQ 3: When do I need to use both a launch and tail cord (launch and receive cable) with my OTDR?

A: You will need to use both a launch and tail cord to measure the end-to-end (insertion) loss and optical return loss (ORL) of a fiber.

OTDR FAQ 4: Must a launch or tail cord (launch or receive cable) have the same fiber type as the fiber network (link) under test?

A: The fiber type of launch and tail cords must match the fiber type used in the fiber link under test.

OTDR FAQ 5: How long should a launch or tail cord (launch or receive cable) be?

A: This depends on a number of factors including:

The length of the fiber link you are testing,

Whether or not the link under test includes a splitter (i.e. whether or not you are testing through an FTTx PON splitter),

The particular model OTDR you are using.

Application examples:

A 150 m launch/tail cord will work for fiber links of 2 km or less, typically found in enterprise networks.

A 1 km launch/tail cord will work for most PON and intermediate length (up to 50 km) point-to-point fiber links.

OTDR FAQ 6: Is an OTDR launch cord (cable) the same thing as a ‘pulse suppressor’ or ‘launch fiber’?

A: Yes, all are long test jumpers housed in portable, compact cases. A typical launch cord contains 150 m to 1 km of fiber. AFL calls most of their launch cords ‘fiber rings’

OTDR FAQ 7: What is the maximum fiber length and pulse width that can be tested with the 150 meter fiber ring?

A: A 1.0 ?s (1,000 ns) pulse width will test up to 40 km of Corning SMF-28e fiber @1310 nm and 50 km @ 1550 nm.

Qualifying factors

A 1.0 ?s is the maximum pulse width that will allow the OTDR to accurately measure the first network connection (mated to fiber ring)

A longer pulse width will allow the OTDR to measure distances greater than 40 km @ 1310 nm, but the OTDR will miss the first network connection

Q: How do I know which range to select on my OTDR?

A: Noyes OTDRs are equipped with a ”Full – Auto” selection enabling the OTDR to automatically scan the network and set the range setting.

At a minimum, the selected range must be longer than the total length of the launch cord, plus the length of the fiber under test, plus the length of the tail cord. For best results, select a length approximately equal to 150% of the longest fiber, plus the length of the launch and tail cords to be tested.

OTDR FAQ 8: How do I know which pulse width to use on my OTDR?

A: If the OTDR has a “Full – Auto”, Expert Auto or Expert Auto-Once mode, the OTDR software will automatically chose the proper range based on the fiber length, and the best pulse width based on that range selected. If the technician is not satisfied with the selected pulse width the OTDR may be switched to “Expert” test mode (if available) and settings may be adjusted manually. The key is to always use the shortest pulse width possible that will satisfy the trace quality and allow the user to see the end of the fiber. Short pulse widths are used for short fibers. Long PW’s are used on long fibers. If the trace quality exhibits excessive noise that cannot be removed by additional averages, select the next higher pulse width.

OTDR FAQ 9: Which pulse width do I use to troubleshoot a long fiber run?

A: Use the shortest pulse width that allows the fault to be located. Repair the fault, and then switch to a longer pulse width to test the entire network.

OTDR FAQ 10: What is an “echo” or “ghost” event on an OTDR trace?

A: An echo occurs when the OTDR receives unwanted multiple reflections. Large reflective events are more likely to cause multiple reflections due to large amounts of energy reflected back to the OTDR. Portions of the energy reflected multiple times result in echos. These waveform artifacts look like real events, however they seldom have loss associated with them.

Source: AFL Global

FIS OTDR FAQ

OTDR FAQ 1: What happens if you feed a optical node with a too high level of light?

Answer:

If the received light level is too high for the detector in an active node, the result of overdriving the detector can cause noise in the signal, or worse case even damage to the unit. The answer is an attenuator. Attenuators are available in either fixed or variable levels of attenuation, and as pigtailed devices, bulkhead adapters, or male-to-female hybrids. Simply measure the power of the signal being received, and subtract the maximum input power of the active equipment from the measured power of the signal to determine the amount of attenuation needed.

OTDR FAQ 2: What is the use of IOR (Index of Refraction)?

Answer:

Our trainer, John Bruno, is recognized throughout the industry. Upon completion of the training course you will receive a certificate of completion from FOWIKI, a certificate which is recognized by BICSI, and is also equivalent to one college credit, which is transferrable to most accredited universities. If you are already associated with BICSI, you can receive a Continuing Education Credit from BICSI as well.

OTDR FAQ 3: Can you tell me the difference or true meaning of a composite cable and a hybrid cable?

Answer:

Can you tell me the difference or true meaning of a composite cable and a hybrid cable. I’ve heard both terms used interchangeably. Are they the same? If so then how would you differentiate between a single-mode/multimode cable vs. fiber cable/copper cable?

OTDR FAQ 4: I am sending video on a singlemode fiber from building A to building B. I would like to see if i can send two cameras back from building B to building A on the same singlemode fiber. If so what equipment will I need?

Answer:

By using WDM’s (Wave Division Multiplexers), you can send two different signals on the same fiber in opposite directions. WDM’s are generally a 1×2 device similar to a coupler or splitter, except that it will separate and/or combine wavelengths on a single fiber. For example, if your current video system is transmitting at 1550nm, you could use a WDM at each end and a 1310nm TX and Rx for the signal in the reverse direction.

OTDR FAQ 5: Need to pad down single mode fiber between a FoxCom fiber transmitter and receiver for Satellite distribution solution. Can you recommend and solution?

Answer:

To “pad down” or attenuate a fiber signal, choices range from fixed level attenuators, or variable attenuators. Fixed attenuators are available as patch cables with built in attenuation, as build-out male to female devices which go on one of the connectors and then plugs into the device, or as bulkheads, which replace a standard mating sleeve with the correct level of attenuation. Variable attenuators for singlemode are usually a pigtailed device with choice of connectors on each end, and a small device in the center of the cable with a tunable set screw to adjust the attenuation level..

OTDR FAQ 6: When testing a fiber using and OTDR, how can the technician determine the correct IOR for the fiber in order to set the proper parameters on the test set to ensure the measurements will be accurate?

Answer:

The index of refraction (IOR) can be found on the specification sheets for the fiber in question. This does actually vary by a small amount from batch to batch, and is usually marked on the original spool from the factory. As a baseline set of numbers, (based on Corning SMF28e, and Infinicor Multimode fibers) singlemode IOR should be set at 1.4682 for 1550nm and 1.4677 for 1310nm , 1.496 (850nm) or 1.491 (1300nm) for 62.5/125 multimode and 1.481 (850nm) or 1.476 (1300nm) for 50/125..

OTDR FAQ 7: We have to test a 9 micron loose tube outdoor fiber and a 50 micron loose tube outdoor fiber on the spool before installation. Is there a bare fiber adapter? How would you suggest the testing be done?

Answer:

The most efficient method of testing bare fiber with an OTDR is to use a pigtail and mechanical splice. It is never recommended that a bare fiber adapter be placed in the OTDR’s test port, as the unpolished fiber end can damage the connection in the port. Connect a pigtail of the correct fiber type and connector to the OTDR or far end of a launch cable. Cleave the opposite end of the pigtail and insert it into a mechanical splice. Cleave the end of your fiber to be tested and insert it into the opposite side of the mechanical splice. By using the “Real Time” function available on most OTDRs you can adjust the position of the fibers in the mechanical splice to get the best throughput. The cable is now ready to be scanned.

Source: FIS