Benefits of Pre-Terminated Solutions – 2

Commercial Office Pre-terminated Assemblies

The completion of the handover of a project is critical, mainly due to the fact that the lease deadline of the end user client’s existing facilities, have to be met to avoid the costly penalty of having to extend their previous lease by a further 3-6 months. This is then compounded by protracted negotiations to get the best price.

Therefore pre-terminated assemblies for commercial office installations is becoming increasingly popular as the project timescales are being constantly shrunk. Some integrators have even taken the step to invest in their own facilities to keep up with the demand.

Whilst it is basically the same product set being used, there are a few key additions and techniques being utilised. One key difference is the lengths involved, they are usually much longer, and if there is a concern about the accuracy of drawings or measurements provided, some companies are opting to minimize their risks by just pre-terminated assemblies the floor outlet end at the factory. In effect producing extremely long outlet to outlet assemblies, that are tested fully if they are below 90m. If over this length, they are tested for continuity before being cut

in half, labelled, packed and shipped to site to be pulled into position onsite.

This approach is being seen almost as a two visit approach, to the floor locations. First stage is to ‘pull’ or lay the loom, usually from the floor location back to the SERs (Secondary Equipment Rooms/Floor Distributors) at which point ‘the floor’ can be handed back to the main contractor for other trades, with the outlets or GOP (Grid Outlet Point) box bagged and coiled for safety under the raised floor and the termination of the other end can continue in the SERs. On some projects a two-shift process is used for speed, with the assemblies being pulled in overnight when the Data Installer has free access to the floors and the termination and testing is done through the day.

Along with the Solid Core Harness links used in the Data Centre we also see the use of longer versions of these assemblies being used as Consolidation Cables in coordination with Consolidation Points that are used to service zones or service areas within a floor or building.

Consolidation Points have been a building block within the standards for a long time however they have only recently started to come into their own due to the additional flexibility they provide in a dynamic office environment that undergoes a lot of moves and changes.

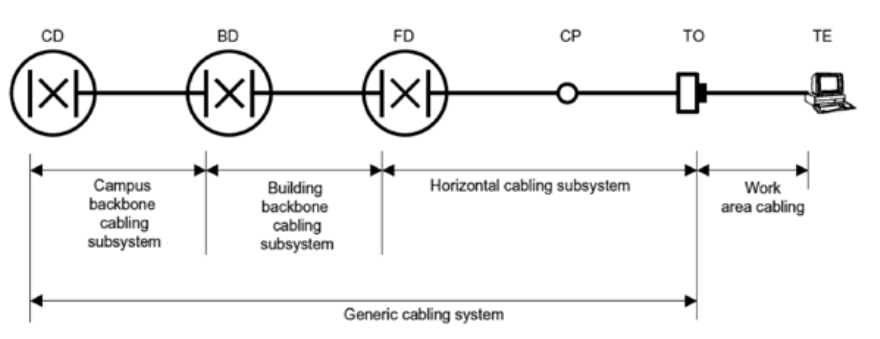

The structure of a generic cabling installation as per EN50173-2

Pre-terminated assemblies can be produced for each element outlined above.

BD= Building Distributor and Solid Core Harness Links

Building Backbone Cabling Subsystem= Backbone Cabling (pre-terminated fibre)

Floor Distribution Cabling Subsystem= Horizontal Cabling

CP= Consolidation Point and Solid Core Consolidation Cables

EO (Equipment Outlet)= Including those housed in GOP boxes

We mustn’t forget that most backbone cabling systems between the MER (Main Equipment Room) and the SERs on each floor are typically fibre, with the occasional copper links as back up.

There is an increasing demand for conventional tight buffered fibre to be pre-terminated offsite. This approach not only saves a great deal of time, it may be essential due to the lack of power onsite for a fusion splicer. The days of ‘glue and polish’ are gone especially with the lower losses of OM4 fibre, certainly I don’t know of anyone who is attempting the manual approach for singlemode.

Pre-fabrication

Another area on the increase is that of Pre-Fabrication where complete sections of buildings are being constructed in a factory style environment and all services are being ‘preplumbed in’ initially it used to just be the power and water but now complete walls for schools and hospitals are having all their services installed in a factory environment including items such as gas/oxygen and IT cabling. The completed wall is then wrapped up taken to site by lorry and craned into position.

Once delivered, it’s a fairly quick and simple task to plug them together and test.

This approach moves the resources to where they are needed and where they perform best. The easy question is where do people perform their best work, a purpose built factory that is dry and warm or a building site open to the elements in the middle of winter?

This approach takes the use of Consolidation Points and Solid Core Consolidation cables to the next logical stage. By running Horizontal Cabling from the SER or Floor Distributor out to a consolidation point close to the location of the final position for the wall or walls for when they are craned into position. The solid core consolidation cables that have been installed within the wall, in the factory are just connected and tested.

This means the time and resources required onsite are dramatically reduced. If everything is labelled correctly it

takes a fraction of the time and cost required for a traditional installation, hence the large number of construction companies that operate in the education and healthcare sectors who are looking to invest heavily in this approach.

Considerations

With all things of this nature, there are some serious ‘Pros and Cons’ to take heed of one size does not fit all, however the Pros certainly outweigh the Cons.

Pros:

- Time Saving

- Cost Saving

- Less Wastage, both packaging and cable off-cuts

- Concentration of valuable resources

- Pre-Tested

- Less Failure onsite

Cons:

- Accuracy in measurement required

- Lacks on-site flexibility for change in program

Benefits of Pre-Terminated Solutions

As can be seen throughout this paper if used correctly PreTerminated solutions can bring a raft of benefits to both the installer and the end-user.

It all comes down to money and all the Pros listed above have a ‘Cash’ value. Yes the assemblies have a higher initial cost as they include the factory termination time, however the savings go beyond this.

Time Saving which in itself brings benefits of cost saving, if you buy the pre-terminated assemblies you don’t need as many onsite engineers pulling cables in and terminating them for as long, saving on the labour bill.

Cost Savings include all the other items of equipment that have to be hired, such as podiums and lifts, if the turnaround is quicker they don’t need to be on hire as long.

Less Wastage, the installer in a lot of cases still has to pay for his waste to be removed from site on many projects, especially if they include cable drums, more importantly the installer is purchasing a more accurate quantity of cable, they are buying by the metre and not by the drum, how many installers have their facilities cluttered up with odd lengths of cables in boxes hoping for a project that will use them up.

Concentration of Resources, rather than having teams of engineers in pulling and terminating in less than ideal

environments, have a select group of specialists pull the assemblies in the right manner, in a controlled environment and then test. This leads to smaller teams for a shorter time and subsequently a smaller labour bill.

Testing on this subject, if they have been tested in the factory sometimes means less testing onsite, It has one Data Centre customer who accepts the factory test results for warranty purposes. All he asks for onsite is random testing within the looms to validate the factory test data, if this is within an acceptable tolerance he is then happy to accept all of them, this has lead to a reduction of testing time by as much as 75%.

Conclusion:

Pre-termination assemblies is not a fad, it is an increasingly popular way of delivering a project in a more timely and cost effective manner. It should not just be confined to the major projects delivered by the large integrators, this approach can provide benefits for all sizes of project.

The Networking is investing and will continue to invest in both products and services that can support any level

of project with many different variations of product presentation, panel to panel, solid core harness links, panel

to GOP, Panel to CP etc. including both copper and fibre, both traditional and MTP.