Cable installation by using high-speed air ow combined with additional mechanical pushing force is called as “blowing or jetting”. Cable blowing is the process of installation of optical ber cable into a pre-installed duct. Compressed air is injected into the duct inlet after few hundred meters of cable is pushed into the duct. Compressed air blows at high speed through the duct and along the cable. The pushing force is applied mainly near the cable inlet by a pushing device. Standard optical ber cables (like uni-tube, multi-tube, unarmored & armored), micro- duct cables, and micro-ducts can be installed by using this method. It is possible to install micro- duct cable using blowing method in continuous lengths of more than 1000 meters depending upon the duct route. There are two methods for blowing which are discussed below.

Method 1: High airspeed blowing

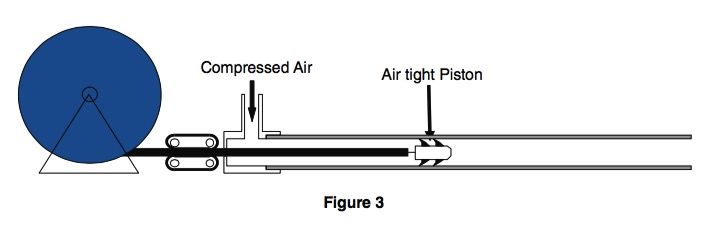

This method requires pushing the cable with tractor mechanism by traction rollers in blowing device for a few hundred meters and then introducing compressed air to make the cable inside the ducts remain in oating condition, which reduces friction between the cable outer surface and duct inner wall by reducing area of contact as shown below in Figures 1 and 2.

Method 2: Push/Pull (Piston) blowing

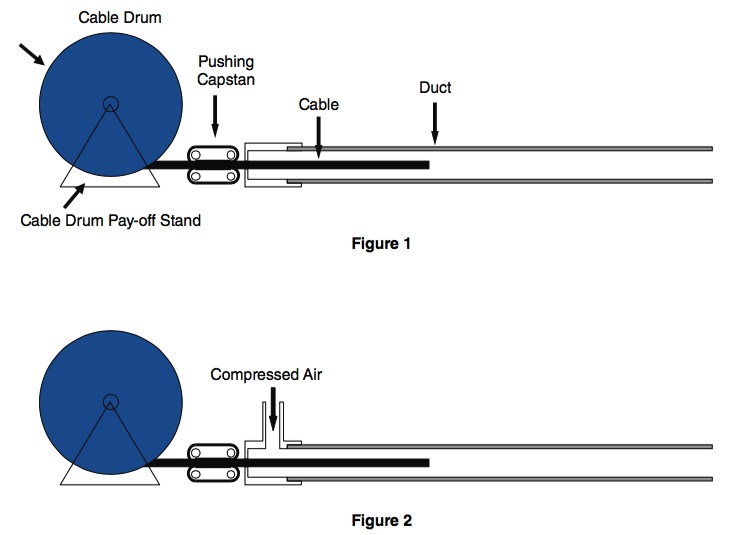

In this type of blowing unit, an air-tight piston is attached to the front of the cable. The air pushes this piston, and the piston “pulls” the cable as shown in Figure 3. Installers should be aware that a pulling force exists in piston blowing, and the pulling force shouldn’t cross the maximum cable tension. This method is preferred for larger size ducts (32/40mm and 42/50mm) and in “straight” trajectories to achieve longer cable blowing distance.