Step by Step guide for FSM-11S Arc Calibration

Atmospheric conditions such as temperature, humidity, and pressure are constantly changing, which creates variability in the arc calibration. This splicer is equipped with temperature and pressure sensors that are used in a constant feedback control system to regulate the arc power at a constant level.

Changes in arc power due to electrode wear and glass adhesion cannot be corrected automatically. Also, the center position of arc discharge sometimes shifts to the left or right. In this case, the fiber splicing position has to be shifted in relation to the arc discharge center. It is necessary to perform an arc power calibration to eliminate both of these issues.

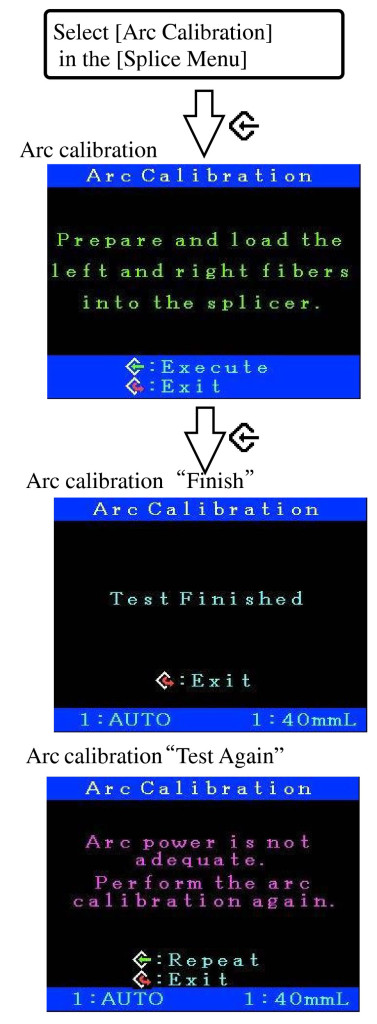

Arc Calibration procedure

(1) Select [Arc Calibration] in [Splice Menu] to display Arc Calibration screen.

(2) Set prepared fibers in the splicer .

(3) The following is performed after pressing .

• Arc calibration is performed automatically when using AUTO mode only. Therefore arc calibration does not have to be performed when splicing in this mode.

• When changing splice modes, except AUTO mode, perform this function.

1. Cleaning arc discharge, The left and right fibers move forward. The splicer performs the cleaning arc discharge.

2. Gap setting, The left and right fibers move closer and stop at the specified gap setting position.

3. Arc discharge, The splicer performs an arc discharge without stuffing the fibers together. The gap between the left and right fibers is increased by the arc discharge.

4. Measurement result, After the arc discharge, the melt-back amounts of the left and right fibers are measured by image processing circuits in the splicer .

(4) The calibration result is displayed after completion.

“T est Finished” message

Arc power and splicing position calibration were successfully completed. Press to exit.

“T est Again” message

The arc power and splicing position calibration were completed but further calibration is strongly recommended, as the change from the previous arc calibration is too large. Press to perform arc calibration, or to exit even though arc calibration is not complete.

• In some cases, multiple iterations of arc calibration are needed until the calibration process is successfully completed and the “T est Finished” message is displayed. Arc calibration can be considered almost complete if multiple iterations are completed without receiving the message.

• A specific numeric threshold can be set so that “T est Finished” message is displayed after a specific number of arc calibrations are performed. See [Other Option] (Page 55) for reference.