Introduction

Fiber optic cable that is capable of surviving the outdoor environment and meets the flammability requirements for use inside buildings offers many advantages to the end-user, as well as the installer and distributor. The use of only one type of cable between and within buildings can save many labor hours and reduce material costs by eliminating the need to splice outdoor cables to flame-retardant indoor cables. The tight-buffered indoor/outdoor fiber optic cables further save on termination costs by permitting direct installation of connectors on the fibers rather than requiring the splicing of preterminated pigtails onto the fibers. Eliminating the splicing not only saves installation costs in time and materials but also greatly improves the cable plant’s reliability by eliminating the discontinuities and stresses on the fibers associated with splices.

Termination and Splicing Costs: Loose-tube Gel-Filled Cable vs. tight-Buffered Cable

Termination and splicing costs of fiber optic cable can be one of the largest line items in an installation budget. A large number of products and alternative approaches make it possible to devise system layouts with considerable variations in installed costs. The choice of the cable type is one of the biggest cost drivers in cable termination. There are three basic cable types used in system installations:

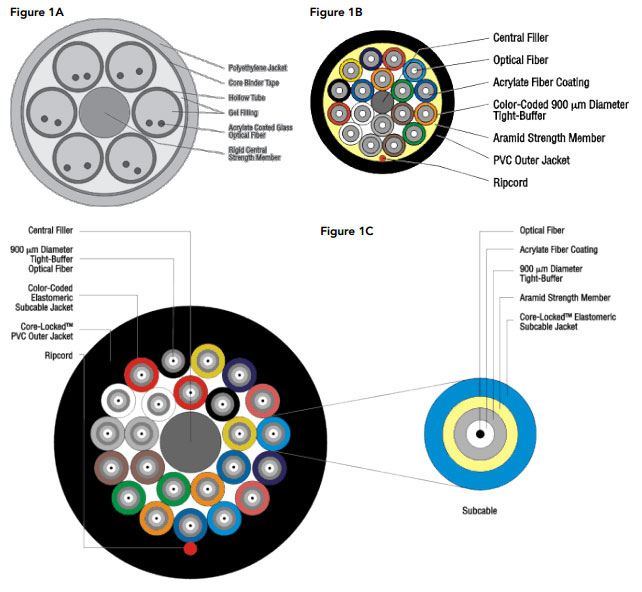

1. Loose-Tube Gel-Filled Cable (Figure 1A)

2. Tight-Buffered Distribution Cable (Figure 1B)

3. Tight-Buffered Breakout Cable (Figure 1C)

Historically, loose-tube gel-filled cable has been used for outdoor long-haul routes (See Figure 1A). Due to the fragile bare fibers and gel filling, which must be cleaned prior to termination, loose-tube gel-filled cable is the most difficult to splice and terminate and also has the highest termination material costs. This cable type must normally be terminated or spliced close to the cable entryway of a building to switch to indoor-style cable, as it is generally incompatible with indoor fire (flammability) codes.

Fibers within the loose-tube gel-filled cables typically have a 250 µm coating. In consideration of this small fiber size, care must be taken to avoid damaging the fibers when removing the outer cable jacket and buffered tubes, as well as when the fiber is being cleaned or spliced. Each fiber must be cleaned to remove gel, and the breakout point of the main cable must be blocked by some method to prevent oozing of the cable gel. This time consuming and labor intensive process adds hidden costs

to the installation of loose-tube gel-filled cable, and it creates another future failure point. In the final termination with connectors, all fibers must be either spliced to pigtails or fed through the tubes of a breakout kit. Due to the fragile nature of the 250 µm coated fiber and the splices or breakout kits, it is necessary to protect them in a splice rack or patch panel housing and to use jumper cables for the final connection to the system electronics.

optical Cable Corporation’s tight-Buffered Breakout Cable

Properly designed and manufactured tight-buffered cable has been amply demonstrated to be suitable for both indoor and outdoor applications. Long before loose-tube cables were introduced, the oldest and longest duration field trial of fiber optic cable in the U.S. was a 22-mile installation in 1978 and located in central Pennsylvania for the Commonwealth Telephone Company of Pennsylvania. It was entirely constructed with tight-buffered cable. The cable system consisted of 10 miles direct-buried, about 10 miles aerial-lashed, and 2 miles in underground ducts. This system was in operation for over 20 years and was retired when their multimode electro-optics became obsolete. All military tactical cables are tight-buffered, and an increasing portion of interbuilding LAN systems are utilizing tight-buffered indoor/outdoor fiber optic cable.

Tight-buffered cables require less care to avoid damaging fibers when stripping back the cable. Each fiber is protected with its own 900 µm diameter buffer structure, which is nearly four times the diameter and six times the thickness of the 250 µm coating. This construction feature contributes to the excellent moisture and temperature performance of the tight-buffered indoor/outdoor cables and also permits their direct termination with connectors.

There are three types of tight-buffered indoor/outdoor cables offered by Optical Cable Corporation:

1. Distribution Cable

2. Breakout Cable

3. Subgrouping Cable

The first cable type, Distribution Cable, is often used as a direct equivalent of loose-tube gel-filled cable because of its smaller size and capability to have a high fiber count (See Figure 1B). Direct connectorization is possible with Distribution Cable because the fibers normally have a 900 µm buffer. Terminated fibers may be directly connected to equipment without use of a patch panel and accompanying jumper cables. Also, no splices or splicing skills are needed, as with pigtails on loosetube gel-filled cables. In situations where the fibers will be mated and unmated frequently, or where there is general access to equipment, it is advisable to place terminated fibers in a patch panel to avoid damage to the connector/fiber interface.

The second cable type, Breakout Cable, has individual subcables within a primary outer cable sheath (See Figure 1C). This cable is the cable of choice for direct connectorization, as each fiber has its own aramid strength member for connector tie-off. Theconnectorized subcables may be directly connected to equipment without fear of fiber damage or connector/fiber interface damage in most situations. Breakout Cable is by far the least expensive and easiest cable type to terminate and requires the least experience on the part of the installer.

The third cable type, Subgrouping Cable, is similar to the Breakout Cable design, except that the subcables contain either 6 or 12 fibers. The subcable is, therefore, similar to the Distribution Cable and the same termination principles apply.

Cable prices are typically lower for tight-buffered cables than for loose-tube gel-filled cables when fiber counts are fairly low. Loose-tube gel-filled cables are lower in price for higher fiber counts. However, higher splicing and termination costs of loose-tube gel-filled cables over moderate-to-short lengths can far exceed the additional cost of tight-buffered cables.

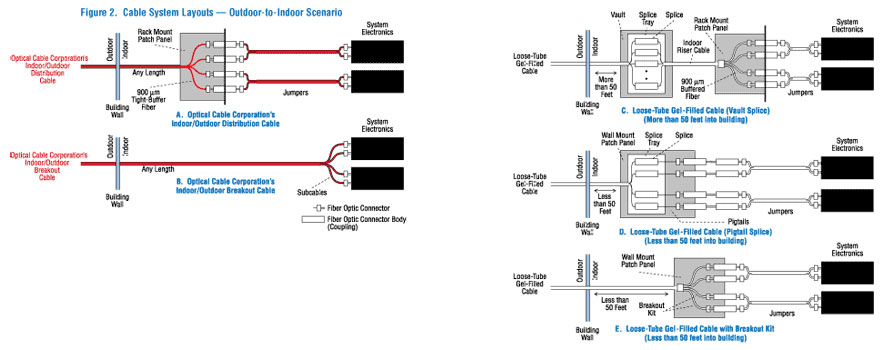

The most common scenario in which termination costs dominate is an interbuilding (outdoor) cable entering a building where the required termination point of the cable is some distance from the building entryway, and it is necessary to switch from outdoor to indoor cable. Outdoor loose-tube gel-filled cable is typically required to be transitioned to indoor cable within 50 feet of the cable entry point to comply with fire codes. However, a tight-buffered indoor/outdoor cable can be used throughout the link, requiring no transitions at the building entryway.

Figure 2 (on the next page) shows the cable system layout for the various cable types. The costs are based on typical catalog prices for elements in the installations. In this scenario, it is assumed there are 24 fibers being terminated. (Most splice trays allow placement of 12 fibers, and most patch panels have port counts which are multiples of 6.) It is also assumed the installer has selected Breakout Cable as the “indoor” cable used from the entry of the loose-tube gel-filled cable to the termination point.

This Breakout Cable would be field terminated on both ends. Single-mode fiber and FC-PC connectors are used in the example. Multimode fiber labor costs would be approximately the same, but connector, jumper, and pigtail prices would be roughly 40% less. Mechanical splicing is assumed, which results in higher material costs but substantially less in equipment and maintenance costs. This cost analysis does not include equipment or tooling costs and attempts, where possible, to assume similar tooling used on each cable type. The actual termination cost will vary with the choice of connector style, connectivity system, and labor rates.

Another popular method of terminating loose-tube gel-filled cable is the use of a breakout kit. This can be used for lower cable counts (normally 24 fibers or less) in place of splicing.

Obviously, in a campus-type environment with many building-to-building runs, the indoor/outdoor capability and ease of termination of Optical Cable Corporation’s tight-buffered cables offer substantial reductions in the total cost of a cable plant installation. Other savings with the use of a single cable type for the indoor and outdoor portions of a network are fewer leftover cable “ends” and less material scrap. Any future emergency repairs are simplified with a single cable type.

Reliability

There are other less quantifiable costs and operational results associated with the selection of cable type and termination approach. One result is overall system reliability. Splices are the weakest link in a fiber optic cable installation. During the splice operation, the fiber is stripped of all its cable, coating, and buffering protection. This leaves the bare glass open to dust, dirt, water vapor, and handling — all factors that have been demonstrated to reduce fiber strength and increase brittleness. The bare fiber ends are then mechanically held in place by a mechanical splice or “welded” together in a fusion splice. Either operation is capable of inducing temporary and permanent stress on the glass. Once completed, the splice is placed in a splice holder, with the lead-in fibers protected only by the 62.5 µm wall thickness of the 250 µm coating. These relatively unprotected fibers are looped around in a small bend radius and are, therefore, potentially under stress in the splice housing. The splice housing may then be “filled” or “sealed” with varying degrees of success for outside use. The splices inside buildings may be held in a cabinet that is open to the air. These cabinets may be located in a basement near a building entrance or in an electrical closet, both of which are uncontrolled environments. The net effect is that in the region of the splices, the fiber is least protected, under the most stress, and usually in a non-ideal environment. This leads to the splices being the item with the greatest failure rate in the cable system. The obvious conclusion is that with the use of Optical Cable Corporation’s tight-buffered indoor/outdoor cables, the splicing is eliminated and the installation reliability is greatly improved.

Maintenance

The use of tight-buffered indoor/outdoor cables greatly simplifies system maintenance and reduces restoration time. For routine terminations often required in moves, additions, and changes, only the skills and tooling for installing optical connectors are needed. In contrast, the loose-tube gel-filled cables require splicing with all the associated tooling and skills. Tight-buffered cables allow some portion of the fibers to be left dark for future termination with whatever type of connectors may be required. The installation of connectors on the ends of the optical fibers is the minimum skill required of the organization responsible for maintenance of a fiber optic cable plant. When using Optical Cable Corporation’s tight-buffered indoor/outdoor cable, it is the only skill required.

Emergency restoration is also made much easier when tight-buffered cables are involved. All of the messy cable stripping, fiber end preparation, and cleaning required for splicing loose-tube gel-filled cables are time consuming and more likely to be successful in a controlled, clean environment. Emergency restoration is most likely to be required in less than ideal, adverse environmental conditions of temperature, rain, snow, mud, etc. In tight-buffered cables there is no gel – the mess and cleaning are completely eliminated. If splicing should be required on a tight-buffered indoor/outdoor cable, the tight-buffered fibers are inherently better protected, and the repair time is greatly reduced.

Optical Cable Corporation’s tight-buffered indoor/outdoor cable is proven to be the cable of choice for interbuilding Local Area Network (LAN) cable installations, with its installation cost savings, reliability improvement, and maintenance advantages.